Engineering & Technology Capabilities

Laser Technology

The adoption of laser technology in the construction industry is rapidly increasing, particularly among contractors involved in large-scale commercial projects.

This growing trend is driven by laser technology’s ability to streamline traditionally manual tasks such as leveling, alignment, plumbing, and squaring. Additionally, it offers significant advantages in specialized areas like excavation and pipe installation, with ongoing innovations continuing to expand its potential impact.

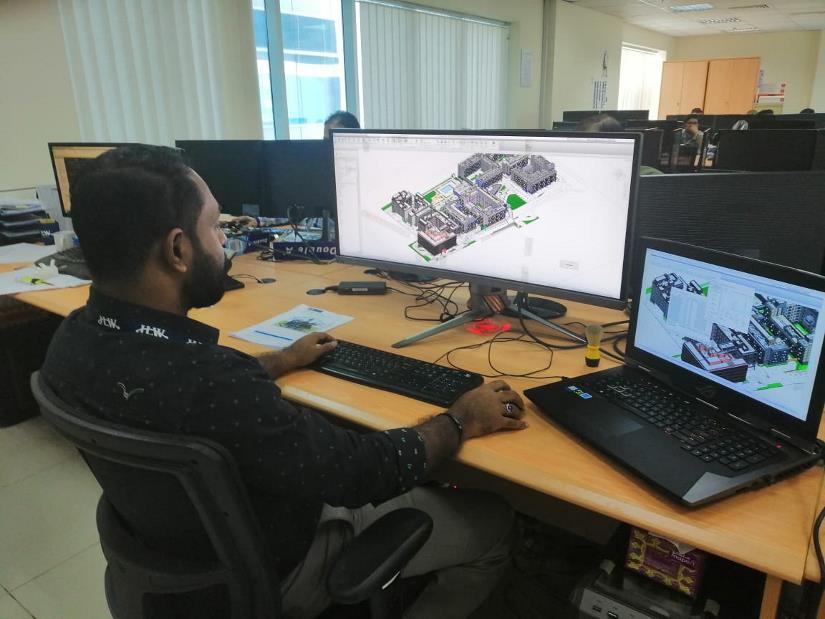

JWL has adopted the use of Trimble’s RTS Robotic Stations and laser setting-out technology to precisely locate the position of each support point for all prefabricated modules, as well as major plant and distribution services.

The Process

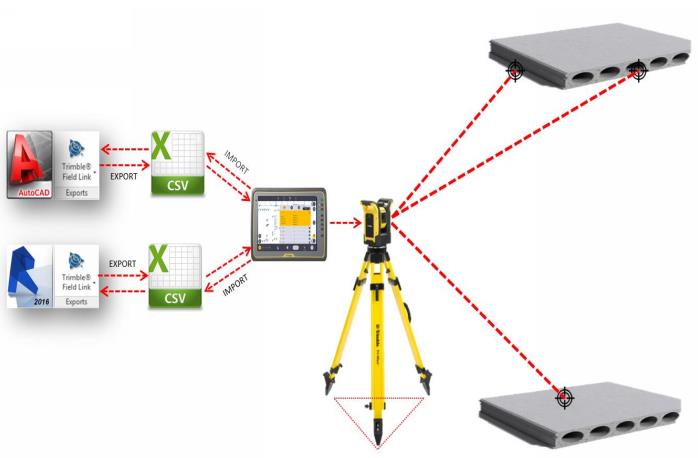

Digital setting-out technology refers to the process of transferring BIM models directly to the job site using a Robotic Total Station paired with a tablet.

This setup enables precise identification and location of specific elements from the model—such as hanger points, builder's work openings, equipment placements, lighting fixtures, and virtually any component defined within the BIM model.

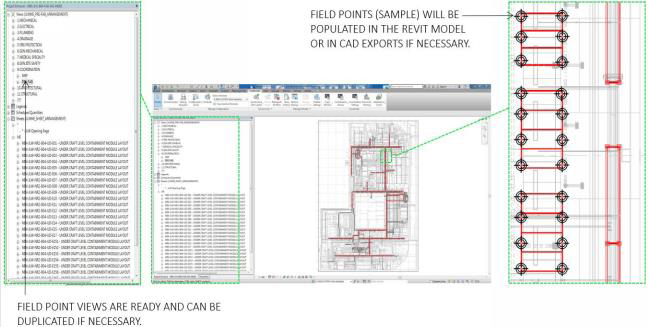

Setting out exact co-ordinates of the support points from the BIM model

Transferring the setout points from our BIM model to the site

In some regions, MEP contractors often arrive on-site later than their counterparts in places like the UK or US. This delay can result from models not being finalized, fabrication timelines not aligning with schedules, or a preference to wait until all structural walls are in place to allow for manual measurements.

Traditional installation methods typically involve manual marking while on step ladders or scissor lifts, often requiring multiple workers for a single support point. Our experience shows that this approach takes up to three times longer compared to using advanced laser-setting technology.

Since adopting this technology in 2017, we have experienced several key benefits:

- Digital setting-out technology allows BIM models to be transferred electronically to the job site, significantly improving installation accuracy—especially for prefabricated MEP modules.

- A single operator can set out 3 to 5 times more points compared to traditional manual methods, which rely on reading drawings and using chalk lines or pencils.

- Reduction in required manpower for layout tasks.

- Enhanced accuracy, leading to fewer errors and less rework.

- Minimizes or eliminates the need for manual field calculations.

- Enables on-site changes to be recorded and fed back into the BIM model, ensuring accurate and up-to-date as-built documentation.