Engineering & Technology Capabilities

4D Simulation

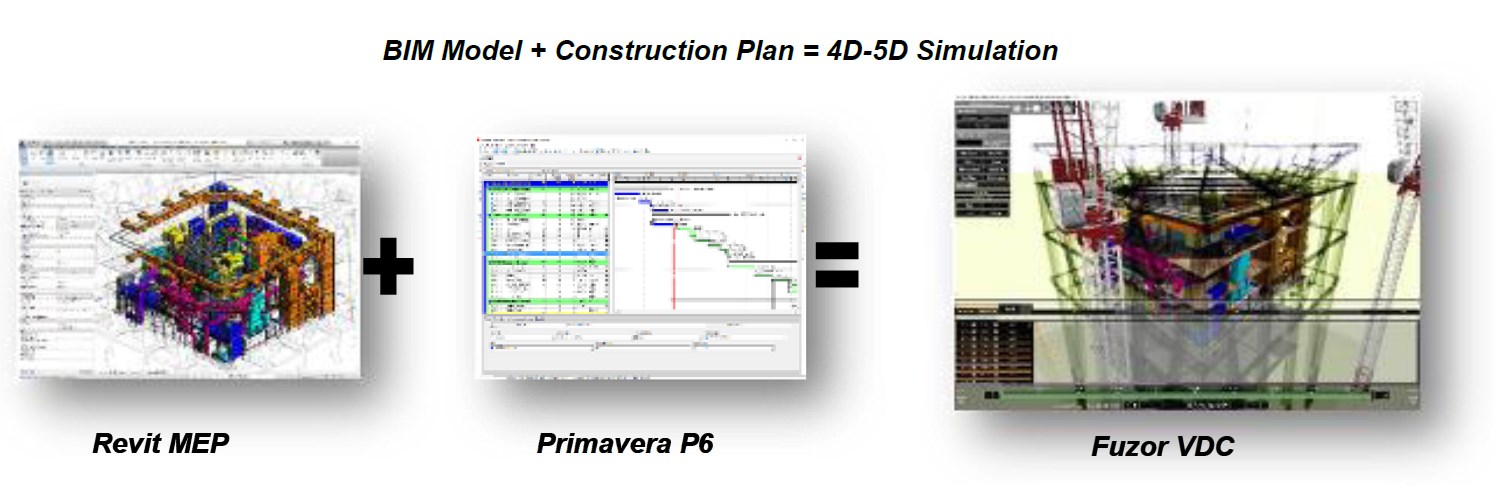

JWL utilizes 4D simulation to accurately plan and visualize every MEP activity, particularly within congested plant rooms and other areas requiring a high level of coordination and detail.

Our 4D construction simulation models enhance collaboration between project teams and clients, enabling clearer communication of project milestones and more efficient construction planning.

We integrate our Revit MEP models with the construction programme to ensure each MEP element—both plant and materials—is linked to a corresponding activity. Using Fuzor VDC (Virtual Design and Construction) as our integration tool, we generate a visual representation of the installation process. This digital simulation supports our construction team in planning logistics, determining the number of daily lifts, organizing material storage, identifying drop zones, and managing on-site material shifting and sequencing effectively.

A clear example of this approach is the planning of the Level 54 plant room at ICD Brookfield Place.

Since the plant room was on the project's critical path, it was essential for the construction team to meticulously plan every lift and installation sequence.

Each MEP element scheduled for installation on Level 54 was individually numbered and assigned a corresponding activity in the construction programme.

This programme was then integrated with the BIM model using Fuzor VDC, enabling us to visually simulate the movement and placement of all MEP elements and plant in relation to time.

This level of coordination allowed us to precisely plan logistics, schedule material deliveries, allocate lifting slots, and manage all material and plant movements within the Level 54 plant room.